MatosPlás, S.A.

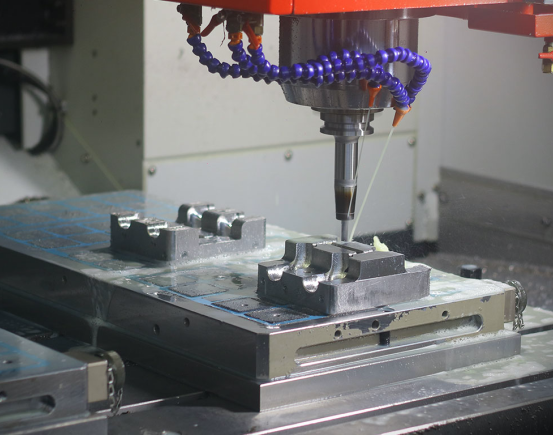

For each order, Matosplás S.A., using its expertise and over 40 years of experience, analyzes the client's information and provides a technical opinion. All projects, from conception to the final product, are developed within the Matos Group companies. We understand the importance of a well-designed mold, using rheological studies, if necessary, to accurately analyze the mold's filling balance, joint lines, warpage, cooling, the need for gas leakage, and more. Our goal, at the beginning of the project/mold, is to identify all potential problems to find preventive measures and solutions.

Injection Production Capacity

With an injection production capacity of 80 to 450 tons, our 16 injection molding machines ensure a response time and volume tailored to our customers' needs. All parts undergo rigorous quality control (metrology), ensuring product quality.

Drying and Dehumidifying capacity of materials

With a Drying/Dehumidifying capacity of up to 200 kg per Hopper/Dryer, our 10 Hopper/Dryer guarantee a response time in terms of time and volume, tailored to our customers' needs.

Overhead Crane Capacity

Type

Standard Double Girder

Nominal Load

16 000 kg

Span

22 500 mm

Installation Height

6 000 mm

Diversified Sectors

Technologies used & Certification

Our Partners

Plimat

Rua da Alemanha Lt. 35

Zona Industrial 2431-959

Marinha Grande

Fax. +351 244 572 320

Plimex

Rua da Alemanha Lt. 6A

Zona Industrial 2430-028

Marinha Grande

Fax. +351 244 573 536

MOLDEMATOS

Estrada da Nazaré N.º2

Moita 2445-573

Marinha Grande

Fax. +351 244 545 701

MATOSGEST, SGPS

Rua da Índia

17,Ordem 2430-370

Marinha Grande

More informations?

Need to talk to us? We're here to help!